Maximize Your Crushing Performance: Discover Top Quality Options in Impact Crusher for Sale

Maximize Your Crushing Performance: Discover Top Quality Options in Impact Crusher for Sale

Blog Article

Revolutionize Your Recycling Operations With an Impact Crusher

One such remedy that has gotten considerable attention is the impact crusher. Exactly how precisely does an impact crusher job, and what are the advantages it can supply? In this conversation, we will explore the inner workings of an influence crusher, the types of products it can process, and provide ideas for optimizing its efficiency.

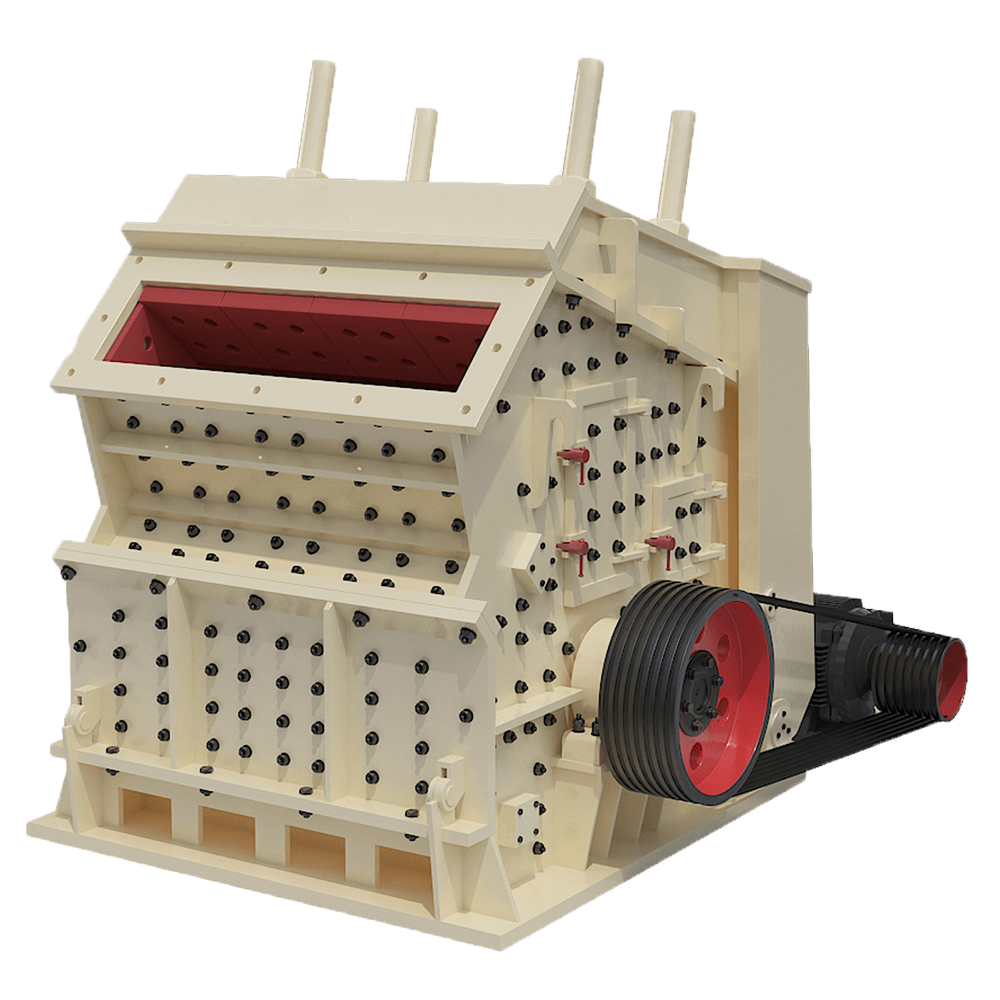

Just How an Impact Crusher Functions

An impact crusher operates by using a high-speed blades and a squashing chamber to efficiently damage down products right into smaller, much more workable dimensions. The fragmented product after that enters the crushing chamber, where it is additional minimized in dimension by the influence pressures generated by the rotating rotor.

Among the vital advantages of an impact crusher is its capability to generate an uniform particle shape. Unlike various other squashing methods, such as jaw crushers, which often tend to produce more extended bits, effect crushers develop cubical-shaped fragments. This results from the high-speed influence pressures created by the blades, which effectively shatter the material and produce an extra regular item.

In addition, influence crushers are very functional makers that can take care of a wide variety of products. From friable and soft materials like limestone to hard and abrasive products like granite, influence crushers can successfully process various kinds of products. This makes them ideal for usage in reusing operations, where different sorts of products need to be processed and changed into reusable items.

Advantages of Utilizing an Impact Crusher

With its ability to generate an uniform particle form and manage a large range of products, the effect crusher offers a multitude of advantages in different reusing procedures. One of the essential benefits is its performance in decreasing the dimension of products. The influence crusher makes use of a high-speed influence force to damage down materials, causing a much more economical and efficient procedure compared to various other crushers. Additionally, the influence crusher has a reduced operating expense as it needs less maintenance and has a much longer life-span.

One more advantage of using an effect crusher is its versatility. It can manage numerous types of products, including asphalt, demolition, and concrete waste. This makes it perfect for recycling operations where different kinds of products are encountered. Furthermore, the effect crusher can generate a consistent fragment form, which is essential in recycling applications. By producing consistent bit sizes, the effect crusher makes sure that the recycled products can be made use of for numerous objectives, such as road construction or as aggregate in new concrete.

Types of Products That Can Be Refined

The impact crusher is qualified of refining a large range of products, making it very versatile in recycling procedures. One of the main products that can be processed by an effect crusher is concrete. The capacity to process such a large range of materials makes the influence crusher an important device in recycling operations, making it possible for the healing and reuse of beneficial resources while minimizing waste and ecological effect.

Tips for Maximizing Efficiency With an Impact Crusher

To optimize the efficiency of an impact crusher and accomplish maximum efficiency, drivers should apply a number of vital techniques. Operators needs to likewise make certain that the effect crusher is effectively lubed to lower friction and stop unnecessary wear and tear.

One more vital suggestion is to readjust the crusher settings according to the certain needs of the material being refined. This can be done by keeping track of the feed dimension, the rate of the rotor, and the space in between the impact plates. By fine-tuning these setups, drivers can ensure that the crusher is operating at its optimum capacity and creating the preferred result size.

Additionally, investigate this site drivers need to thoroughly choose the ideal feed material for the effect crusher. This entails understanding the attributes of the product and its impact on the crusher's performance. It is very important to avoid feeding large or exceedingly tough products that might create damage to the equipment or lead to inefficient squashing.

Lastly, operators must frequently keep an eye on the performance of the impact crusher and make adjustments as required. This can be done by examining the item top quality, manufacturing price, and power consumption. By continuously maximizing the crusher and examining's efficiency, drivers can take full advantage of performance and reduce downtime.

Ecological Effect of Using an Effect Crusher

On a regular basis keeping track of and maximizing the performance of an impact crusher not just makes the most of performance and decreases downtime, yet it also permits operators to examine and mitigate the environmental influence of using the crusher. The ecological impact of utilizing an impact crusher can be considerable, specifically if proper actions are not taken to reduce it.

To mitigate this impact, operators can implement various steps. Furthermore, routine maintenance and assessment of the crusher can aid recognize and deal with any issues that may lead to enhanced dust discharges.

An additional ecological concern is the noise produced by the effect crusher. Extreme sound can interrupt neighboring residents and wildlife, and it can likewise have unfavorable wellness effects on the operators operating in close proximity to the crusher. To reduce sound pollution, drivers can utilize noise-reducing procedures such as sound barriers or units around the crusher. They can likewise arrange crushing operations throughout times when noise impact is minimized, such as during daytime hours when sound from surrounding activities is Continue greater.

Verdict

Finally, integrating an impact crusher into recycling procedures can reinvent the process by effectively squashing different materials and improving performance. The advantages of utilizing an effect crusher include lowered waste volumes, boosted production prices, and improved product top quality. By following pointers for making the most of performance and thinking about the ecological impact, recycling procedures can i was reading this significantly take advantage of using an effect crusher.

The influence crusher uses a high-speed effect pressure to damage down materials, resulting in a much more cost-efficient and efficient procedure contrasted to other crushers. The capability to refine such a broad variety of products makes the impact crusher an important device in reusing procedures, enabling the healing and reuse of useful sources while reducing waste and environmental effect.

Regularly maximizing the performance and keeping track of of an effect crusher not only makes best use of efficiency and reduces downtime, but it also allows operators to evaluate and reduce the environmental impact of using the crusher. The environmental impact of using an impact crusher can be significant, especially if proper measures are not taken to minimize it. By following tips for making the most of efficiency and considering the environmental impact, reusing procedures can considerably profit from the use of an impact crusher.

Report this page